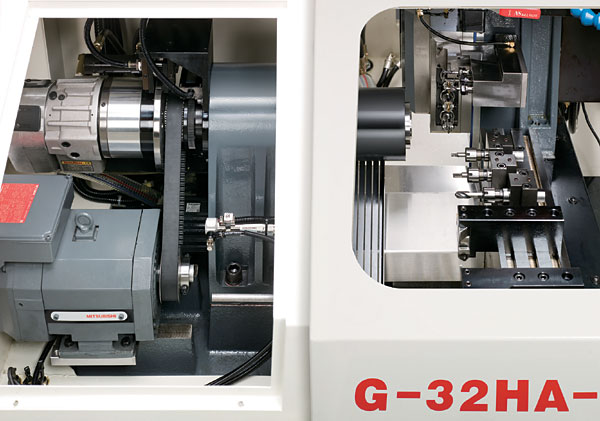

TAIWAN FIXED HEAD LATHE MACHINE - G-32HA-DE

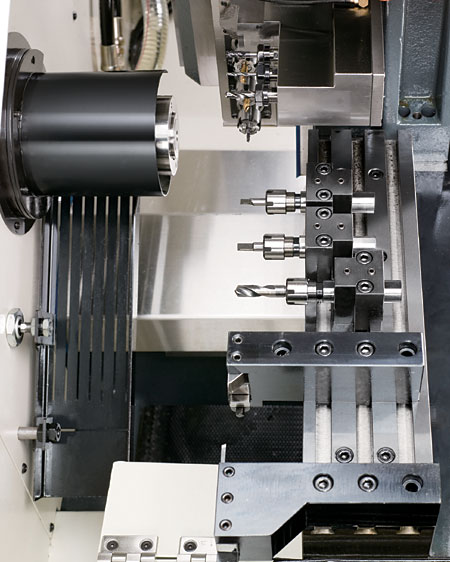

1. Specialized precision CNC lathe for component machining, ID / OD / cross / off-center end working can be done on the same single machine.

2. Cs contour axis, available for arbitrary degree spindle-locked indexing or contouring (like engraving, etc).

3. On request, special-purpose CNC machine for screw driver manufacturing is also available.

4. Center height of OD tool can be adjusted easily.

5. Interchangeable between cross rotary ER16 collet holder & fixed OD tool (?18mm) holder.

| Model | : | G-25/30/32 HA-DE |

| Axis name | : | X, Y, Z, C |

| Bar capacity | : | 25 / 30 / 32 mm |

| Max. turning length | : | Bar diameter x 3 |

| Spindle bore | : | 34 mm |

| Collet type | : | 161E / 163E / 164E |

| 3-jaw chuck size | : | 5 inch |

| X-axis travel (Radius/dia.) | : | 340 / 680mm |

| Z-axis travel (if collet) | : | 95mm (Between collet and cut-off tool holder) |

| 8-position tool turret | : | None |

| Spindle motor (rated/15min.) | : | 2.2 / 3.7 KW |

| Max. spindle speed | : | 6,000 RMP |

| Live tool motor/speed | : | 0.75 kw / 4000 RPM |

| Axis motor | : | 0.75 KW |

| Face live tool No s/collet | : | 3/ER11 (option 2/ER20) |

| Cross live tool No.s | : | 3 / ER16 |

| OD tool shank size | : | 16 x 16 mm |

| Fixed ID tool collet | : | ER16 |

| Boring tool shank dia. | : | 20mm |

| Spindle center height | : | 900mm |

| Packed machine size | : | 1,850 x 1,550 x 2,080 mm |

| Packed machine weight | : | 1450kg |